Build directions

Heatsinks and cooling

A standard heat sink with the same width as the PC board (100 mm) can be used if you have only one module. This heat sink with the width 200, 300 or 400 mm can be used if you would like to use more PA 03 modules together. A thick-walled square tube (wall thickness of 5 mm and more), a square bar or U-form profile can be used to convect the heat from the LM4780 to the heat sink.

The LM4780 mounting

The heatsink is floating which means that the LM4780 doesn't need any insulation but heat compound is need to ensure proper heat transfer.

The regulator mounting

The regulators need to be insulated but no heat compound is needed but no harm to use some.

Click on the picture to get a larger view.

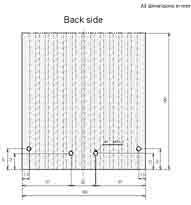

Picture shows how multiple boards can be attached to one large heatsink.

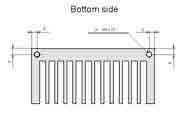

Click on the picture to get a larger view.

Picture shows the drill plans for the heatsink

PC board mounting and soldering

The board is quite easy to build but the following order is recommend although you can do as you'll like. The important thing is to be able to solder and mount the LM4780 in a practical way. Don't have the Q1 mounted when you are mounting the LM4780. It's easier if you can fiddle with the pins of the LM4780 without problems.

- Match resistors for the input buffers and maybe also the LM4780

- Mount the smallest parts such as resistors, diodes, zeners

- Mount film capacistors

- Mount small electrolytic caps

- Ic's

- Heatsink and mount the LM4780 and regulators. See details above.

- Transistors

- Fuse holders

- Big caps

- Inductors (don't forget to remove the insulation on the wire!)

- Rectifier bridge

- Relays

- Connectors

You should start with mounting of the smallest parts. Insert them to the PC board and solder them. During the soldering the parts should lie on a semi-hard pad (rubber or felt liner). Start with diodes and continue with resistors, capacitors and transistors. In the end fasten the heat sink to the PC board, screw down stabilizers, LM4780 and solder them.

PA03 PC board is made of laminated plastics with 70 µm copper clad (a double copper thickness against the standard one) and its thermal persistence is higher than usually. You need to hold your soldering iron a bit longer on the PC board. You should always use a high-quality tin (Crystal 502 made by Multicore or a similar one). The board is leadfree so you can use any tin.