Why did I design this?

Some people feel that they need a faster rectifier bridge than the normal 1-50 µs in 50/60 Hz applications. I have seen on the internet that there are few products out there which can take max 2-3 A because the don't have any cooling arrangements.

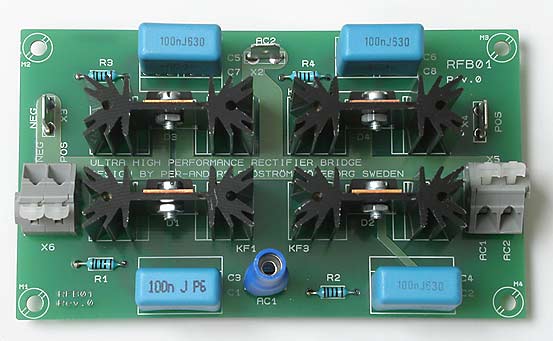

My design can take a lot more current because I have four heatsinks, one for each diode.

The schematic

The schematic. Please download it if you want to take a closer look.

The rectifier bridge is built by four ultra fast recovery diodes plus four heavy duty polypropulene capacitors PHE450 from the famous swedish company EVOX-RIFA. As an option you can choose to have only a capacitor or a capacitor plus a resistor. The values can go from 1-100 nF and 1-100 ohms and to really determine the exact value you must have spectrum analyzer which no DIY'er have I suppose. 100 ohms and 100 nF is a good start I think. You don't have to use the type of capacitor I have suggested. The pcb has holes for almost any type with pin spacing, 0.2, 0.25, 0.3, 0.35, 0.4, 0.45, 0.5, 0.55 and 0.6"inch, from 5 to 15 mm.

Top view of the RFB-01. Note that you only have to solder one type of connectors.

Virtually any diode, especially if they have TO220 case, fits. You can even use regular round ones. MUR820 (200V, 25 ns) and MUR860 (600V, 45 ns IR, 25 ns ON-Semi) seem to be good choices. I have chosen MUR820 because ELFA has it.

Two manufactures of diodes can be found here:

If you plan to use this bridge in a preamp, you won't probably need any heatsinks. If you plan use this bridge in a heavy duty application you must use heat compound between the diode and the heatsink. This compound is usually white and I recommend you to use a silicone free product because the silicone has the tendency to creep all over the place and collect dust.

You can connect the bridge with ordinary cables but max 2.5 square millimeters if you use Wago-connector. Other screw terminals may take bigger cables. As an option I have added lug connectors. Then you can use cables with an area of 6-10 square millimeters.

As a general rule for this project, use any component, audiophilic or not. As long as it's fits for the application it's OK to use it.