Circuit description

Please download all the schematic pages and print them out. It's much easier to understand what I'm talking about if you look at the circuits at the same time. I will only talk about the left channel. The two channels are identical.

The amp consist of a couple of blocks

- Opamp, extremely low noise och low distortion

- Crossover distortion reducer with a JFET or a BJT or a simple resistor

- Integrated buffer or discrete buffer with power transistors

- Feedback network, RIAA-network, with option for Linear Tech original (see picture below) and my own

- DC-servo with chopper stabilized opamp (ordinary precision type opamp can be used also)

- Offset adjusting pots (if you don't use DC-servo)

- Stabilized power supply, except for transformer (or transformers)

The main idea

The main design idea is taken from the datasheet of LT1115 which is an excellent opamp with extremely low noise, one of the lowest in the market despite the fact that the chip is nearly a decade old.

The picture above shows the original circuit which I think is rather well-done but nevertheless a few enhancements can be done.

The pcb is designed so you can build an exact copy of the original, therefore the RIAA network may seem a little bit odd in my design but if you take a closer look there are two different networks. The main thing I personally don't like is the 2200µF capacitors for DC-removal. I use a DC-servo instead. I have also trimmed the RIAA network in order to be even more accurate.

The picture shows the RIAA curve of the original design. Download the datasheet of LT1115 if you want a clearer picture.

RIAA-amp amplifies the signal and correct it according to the international RIAA-curve.

The capacitors for the RIAA-network should be high performing and with tolerance of less than 5%, preferable 2.5%. If you can't get hold of precision caps it's OK to measure up 5 or 10% caps. I think both polycarbonate and polyester will work rather well but I recommend polypropulene.

I you want any help measuring caps I can do that for you. I have a 0.25% LCR bridge. If you buy something from me you will get this for free otherwise I'll do it for 2 x postage.

No capacitors in the signal paths - DC-servo

A DC-servo eliminates the input offset, which always are present. No capacitors are the signal path. Therefore the offset voltage is about 1000 (MM mode) to 10000 (MC mode) times higher than in a normal AC-coupled amp. The residual offset comes from the DC-servo itself. The offset voltage is the DC-voltage at the output when you have no signal applied to the input. It comes from deficiencies in the input stage of the opamp.

LT1115 together with C11-C13 gives you excellent DC performance but if you like me don't like these caps you must use a DC-servo. It's virtually impossible to get good DC-performance without some kind of servo (based on good opamps).

The DC correction circuit here is kind of special. You can't use this approach to any opamp. You can use similar approach for other opamps but this is nothing for a newbeginner. It takes deep knowledge of the opamp and what's inside. Using the "Trial and error" method is doomed to fail. My method here is to manipulate with the offset trim inputs. These pins are directly connected to the input stage of the opamp. The alone resistor R29 together with R28 creates a basic balance. When R28 is raised from ground or lowered from ground you will get a small change in the balance of the input stage.

DC is sensed at the output and then integrated in the chopper stabilized opamp which creates an error voltage fed back into the main opamp.

How does the DC-servo work in detail?

The servo has some difficulties to be connected conventionally to the junction of the inverting input because of the low resistor values. The servo will consume a great deal of power but otherwise it's not a problem. My solution to manipulate with the offset adjusting inputs works only for LT1028/LT1115. It may work for other opamps but most likely the connection must be done with different resistor values and/or circuits. This is nothing for a newbeginner. It requires a great deal of knowledge in order to succeed.

Through R28 a small current is either injected or drained. C28 makes sure that no audio signal goes into the servo and also that the servo not introduces any noise.

You can choose from four options:

- Chopper stabilized operational amplifier with external auto-zero caps, MAX420, R25-R29, R74-R78, C24-C30, C77-C83, IC3 and IC8.

- Chopper stabilized operational amplifier with internal auto-zero caps, MAX430, R25-R29, R74-R78, C24, C25, C28-C30, C77, C78, C81-C83, IC3 and IC8.

- Conventional precision operational amplifier, R25-R29, R74-R78, C24, C25, C28-C30, C77, C78, C81-C83, IC3 and IC8 (OP07 or similar), P3, P7 or P4, P8, depening on chosen opamp.

- Plain trim potentiometers, P1, P5 or P2, P6, depening on chosen opamp.

All opamp choicies are good but they are listed in performance order. I don't recommend trim potentiometers but I have made room for them anyway. Chopper stabilized DC-servo is a nice overkill. Never seen before in a RIAA amp! Prove me wrong! Still if you want the job to be done with some technical sanity, use a opamp, a decent type with good DC-performance, slow and with low noise. The speed of the opamp should be not more than 1 V/µs. OP07 is a typical example of what you need.

The output stage

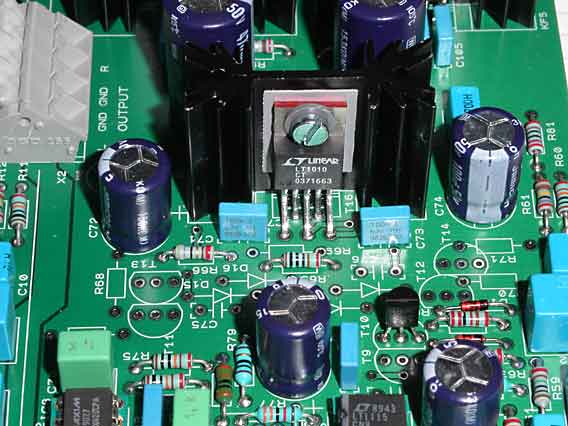

I have made options for two different kinds of output stages, one regular bipolar one with fast small power transistors and one integrated with the buffer LT1010. With this two choices I have made the design a little bit more "timeless". If you easily can get the LT1010, use it! My recommendation.

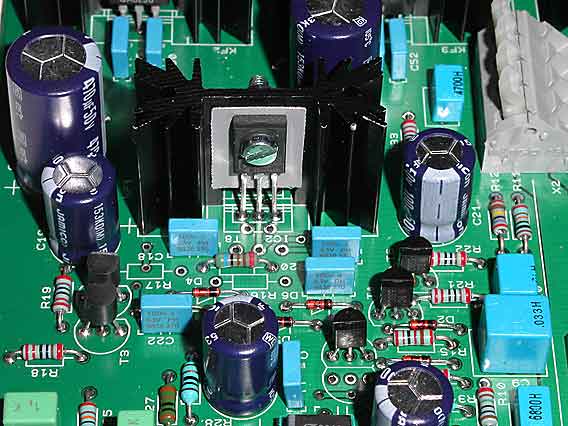

The bipolar (BJT) output stage

Click on the picture to get a larger view.

The monolithic (LT1010) output stage

Click on the picture to get a larger view.

The Class A circuit

You can choose from three options:

- JFET, current source, T1, T9, R14 and R63. The value of these resistors need probably adjustment, higher value, 500 ohms or higher.

- BJT, current source, T2, T10, R14, R15, R63, R64, D1, D2, D13, D14

- Plain resistor, R14, R63 connected directly to the output. Suitable value 6.8-10 kohms.

The class A circuit can be omitted but it makes most benefit when the load from the opamp is small like when you use the LT1010 buffer. This circuit is very popular in the internet DIY community, never seen though in real life, in commercial products. It's cheap, easy to implement, doesn't do any harm for sure, can do good, not always the case. No harm in testing! Even a serious firm, Linear Technology suggests it.

Feedback

I have made room for additional feedback networks. This is only necessary if you have difficult loads. C3, C50, R7, R56, C5, C58. You may be forced to use them if you use the amp in some other application.

The input filter

It's very important to tune the input impedance in order to achieve flat frequency response. R1 together with R50 creates 47 kohms needed for most MM pickups and R3, R52 is for MC pickups.

R2, R51 together with C2, C54 is an EMI-filter. In order to achieve the lowest noise possible R2, R52 should be 0 ohm if you don't have any RF interference. If you have some trouble start first with:

- a wire with ferrite beads

- a bigger ferrite inductor with one or few windings

- an inductor 100µH to start with

- a resistor, 10-100 ohms (avoid due to increased noise, especially in MC mode

The output filter

At the output there is a filter, R32, R33, R81, R82, C31, C84. This filter serves three purposes:

- The last part in the RIAA network. Due to properties in using a non-inverting amp you can't get gain lower than 1. These creates a "zero" which bends the frequency curve "upwards" which is this case gets "horizontal". The results is small error. Even larger error is created of the R8, R58. These resistors are to limiting the minimun gain. LT1115 isn't 100% stable at gain lower than 3 without reducing the slew rate. The resistors also limits the load at high frequencies.

- Short circuit protection. These resistors creates an extra protection against faulty loads.

- RFI protection. You will get a good RFI protection "for free". No harm in that!

Correct pickup load

It's important especially for MM-pickups to have correct load. Too little capacitance creates a sharp resonce peak at 8-20 kHz which can cause a sharp treble sound. The resistance is determined by R1, R50 (MM), R3, R52 (MC) The right capacitance, C1, C54 (MM), C2, C55 (MC) is also important, especially for MM-pickups. 100-500 pF is normal values. Consult the pickup manufacturer for the right value. MC-pickups demands much larger capacitance C2, C55. I have chosen 10 nF. Normally MC don't need any input capacitor but to be sure, consult the datasheet of the pickup. With jumper J1 you can in an easy way change load. The best solution is to solder the jumper pins (and exclude the jumper itself) but I think the contact in the jumper is quite good.

Component choices

I have nothing against "audiophilic" components but this design requires normal standard good performing industrial parts as a good start and will work correctly if the recommend parts are used. Feel free to change the parts you like but you must have control over the important electrical parameters of each part. I think that some of the "audiophilic" parts are just plain froud. They have absolutely no documented "audiophilic" features what so ever. Same parts are only known but rumours over the internet and magazines. In many cases no double blind tests have taken place.